Quality Inspection for Used Pdc Bits - Factory of Core Barrel with Tri-Cone Roller Drill Bit – YINHAI

Quality Inspection for Used Pdc Bits - Factory of Core Barrel with Tri-Cone Roller Drill Bit – YINHAI Detail:

Basic Info.

|

Cutting Diameter mm |

Shell Height mm |

Shell OD mm |

Shell Thickness mm |

Stiffening |

Stiffening Ring Height mm |

QTY of Roller Cones (PCS) |

Weight(KG) |

YH BRAND TYPE |

|

φ600 |

1200 |

500 |

20 |

20 |

200 |

4 |

600 |

YH600-1200-4 |

|

φ800 |

1200 |

700 |

20 |

20 |

200 |

6 |

800 |

YH800-1200-6 |

|

φ900 |

1200 |

800 |

20 |

20 |

200 |

7 |

820 |

YH900-1200-7 |

|

φ1000 |

1200 |

900 |

20 |

20 |

200 |

8 |

980 |

YH1000-1200-8 |

|

φ1200 |

1200 |

1100 |

20 |

20 |

200 |

10 |

1300 |

YH1200-1200-10 |

|

φ1500 |

1200 |

1400 |

20 |

20 |

200 |

12 |

1600 |

YH1500-1200-12 |

|

φ1600 |

1200 |

1500 |

20 |

25 |

200 |

13 |

1740 |

YH1600-1200-13 |

|

φ1800 |

1000 |

1700 |

20 |

25 |

200 |

15 |

1950 |

YH1800-1000-15 |

|

φ2000 |

800 |

1900 |

25 |

25 |

200 |

16 |

2350 |

YH2000-800-16 |

|

φ2200 |

800 |

2100 |

25 |

25 |

200 |

18 |

2700 |

YH2200-800-18 |

|

φ2500 |

800 |

2400 |

25 |

25 |

200 |

21 |

3000 |

YH2500-800-21 |

|

φ2800 |

800 |

2700 |

25 |

25 |

200 |

24 |

3800 |

YH2800-800-24 |

|

φ3000 |

800 |

2900 |

25 |

25 |

200 |

25 |

4300 |

YH3000-800-25 |

| YINHAI Brand Core barrel can be produced depending on customization. | ||||||||

We are the 100% real manufacturer and also produces other sizes and types of rock bits besides above products.

Welcome video call to inspect factory

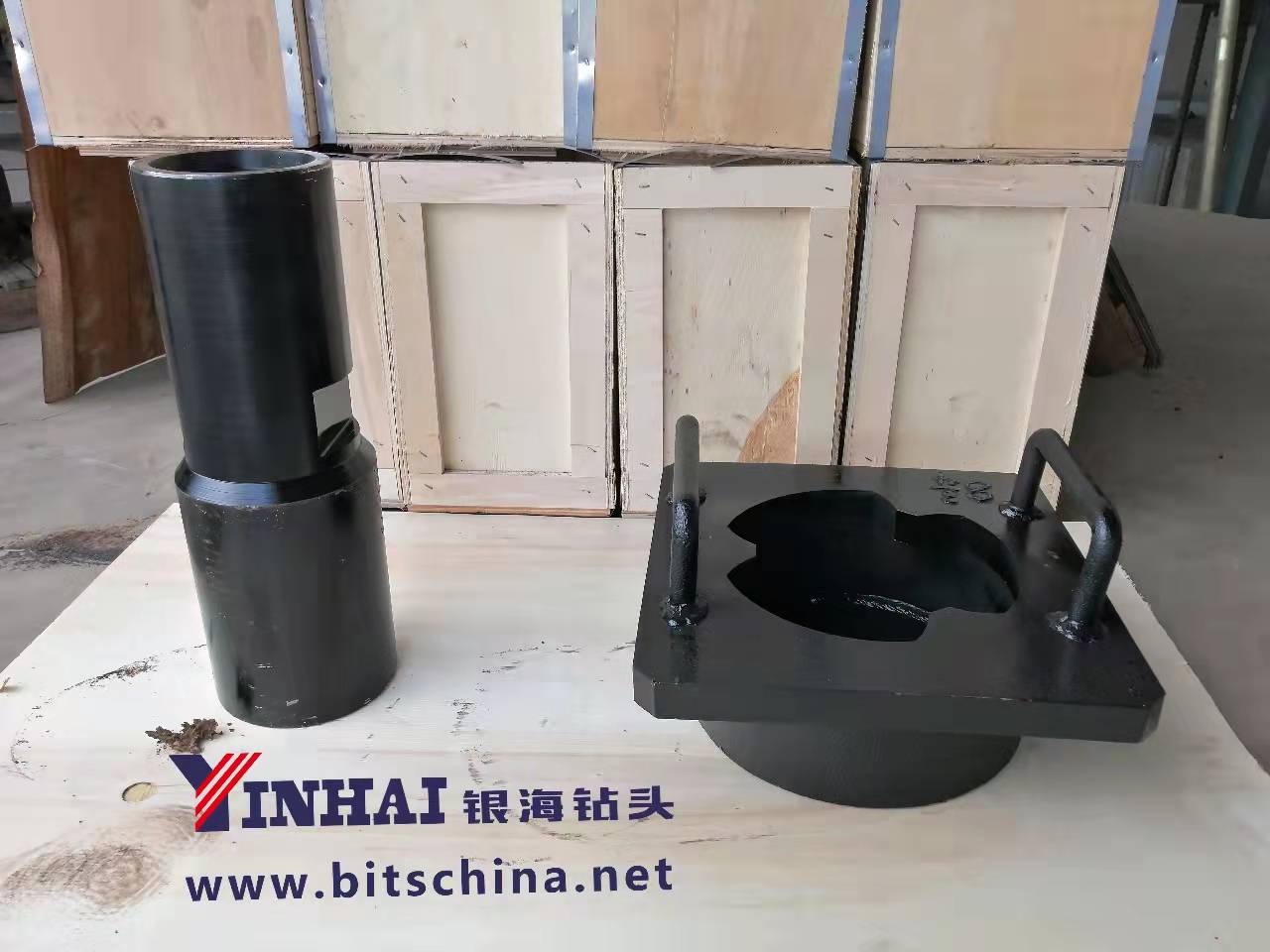

YINHAI CORE BARREL WITH ROLLER BITS

Overview of The Core Barrel with Roller Cone Bits

The Core Barrel with Roller Cone Bits uses high carbon steel and a special bit Angle to maintain drilling strength and efficiency.

There are three types of core barrels

A. Core barrel with bullet teeth is used for cutting an annular ring in rock or concrete(also reinforced concrete).

B. The Core Barrel with Roller Cone Bits is used in very strong rock formations(compressive strength >100Mpa).

C. Cross cutter core barrel is mainly used to break rock cores that remain in the borehole after using a core barrel, also suitable for drilling hard, jointed rock(<100Mpa) and for penetrating through layers containing boulders.

Applicable formation: dense sand, gravel, and medium hard rocks, etc.

The Structure of Core barrel :

- With dual accident prevention function, the core barrel is equipped with a twist-off prevention device and an accident prevention cable. Once the rotary shaft breaks, the core barrel will not fall into the hole.

- Set limit height device, when drilling hard rock, it will not cause the core to wear and destroy the upper mechanism due to the long-time drilling (long stone core).

- Compression spring device, This device ensures that the two bucket flaps are stretched to the maximum when the core barrel is drilled into the hole or during drilling, and it will not tremble due to the jitter of the drill rod, so that it can prevent the stone core from being squeezed between the bucket flap and the core barrel wall, and cause broken the bucket flaps.

- This Core barrel can be used not only in hard rock but also in pumice formations with gravel diameters greater than 250mm.

Product detail pictures:

Related Product Guide:

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for Quality Inspection for Used Pdc Bits - Factory of Core Barrel with Tri-Cone Roller Drill Bit – YINHAI , The product will supply to all over the world, such as: Portland, Leicester, Manchester, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!