OEM/ODM Factory Tricone Bits 12 1/4 - Cutting Od1100mm Core Barrel with TCI Single Roller Cone for HDD Drilling – YINHAI

OEM/ODM Factory Tricone Bits 12 1/4 - Cutting Od1100mm Core Barrel with TCI Single Roller Cone for HDD Drilling – YINHAI Detail:

Basic Info.

Core Barrel drill operating procedures

1)Before running the core barrel, the flexibility of the mechanism must be checked at the orifice.

2)Bucket flaps must enter the hole when fully stretched.

3)The initial drilling can not be pressurized, and then gradually pressurized after the backdrilling is stable. At this time, the core barrel should not appear to skip(move up and down).

4)If countersinking or stuck drilling occurs during drilling, stop pressurizing and do not use reverse drilling

5)During the drilling, it was found that the slewing resistance suddenly increased. At this time, it can be preliminarily judged that the core has been broken, and it can be reversed 2 to 3 times, and the core barrel can be lifted.

6)During the drilling process, a sudden pressure loss is found, that is, there is no resistance when turning. You need to stop drilling immediately and check to prevent the rotating shaft from breaking.

FAQ:

1.Q:What kind of packing do you have?

A: Plywood case free of fumigation;cartons;packing can be customized.

2.Q:What is your price advantage?

A:We are 100% factory directly sales,API production process guarantee,Provide customized services for brand processing.

Reduce the cost of drilling for you, worry free after-sales service.Welcome video call to inspect factory.

Product detail pictures:

Related Product Guide:

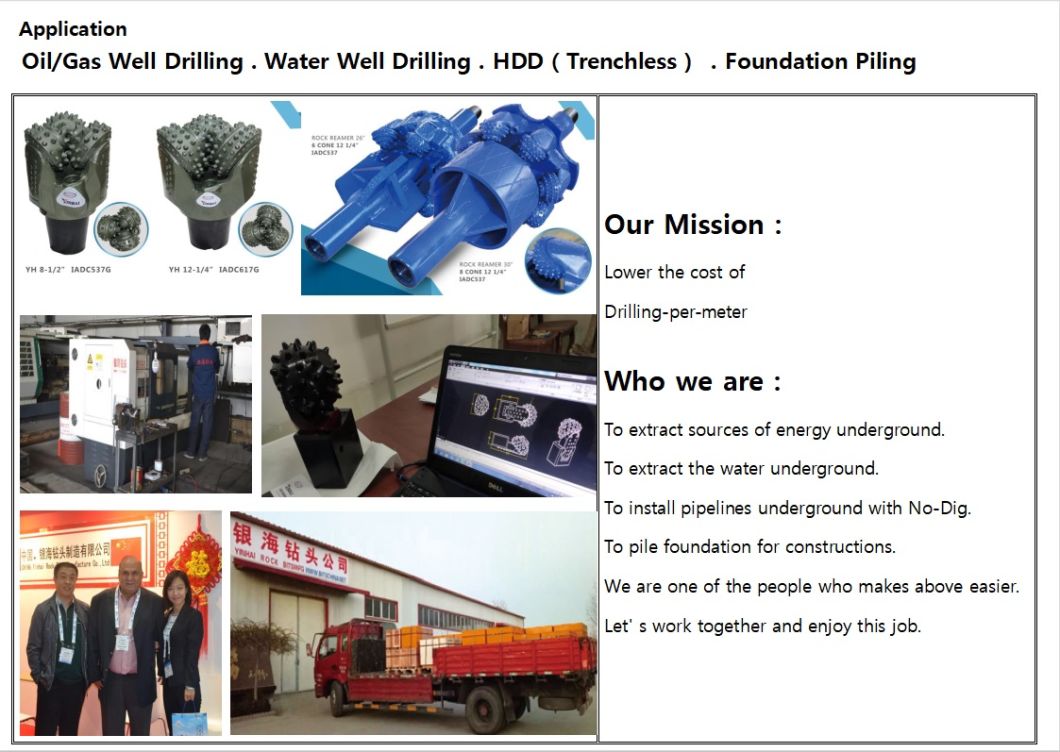

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with OEM/ODM Factory Tricone Bits 12 1/4 - Cutting Od1100mm Core Barrel with TCI Single Roller Cone for HDD Drilling – YINHAI , The product will supply to all over the world, such as: South Korea, Spain, Detroit, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.