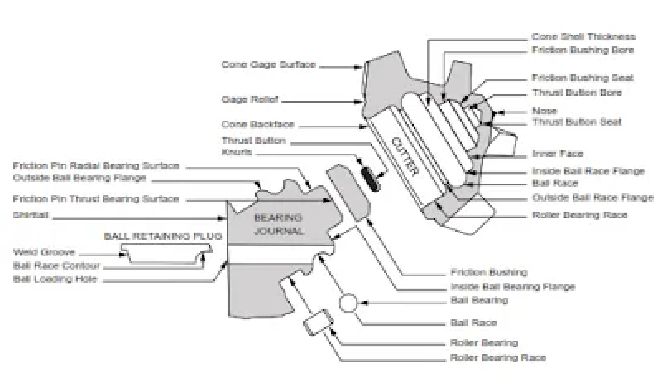

Various types of Rock bits and Roller Cone Drill Bits lubrication system used for bearings protection. Early system including use the drilling fluid as the lubricants, while more recent system use greases for lubrication. Drilling fluids containing abrasive solids to be a limited factor relative to long bit runs and seldom used as the lubricant in present-day bits. For Example the cones of a tricone bits , roller cone drill bit are mounted on journals as shown in below design.

Drill bits,Tricone bits Rock Roller Cone Drill Bit Bearing Design

Three Common Types Of Bearings Design Used In These tricone bits rock Roller Cone Drill Bits:

1.Roller bits bearings System, which form the outer assembly to support the radial loading (or WOB)

2.Ball bearings System, which resist longitudinal or thrust loads and also help to secure the cones on the journals

3.A friction Bearing System, in the nose assembly which helps to support the radial loading. The friction bearing consists of a special bushing pressed into the nose of the cone. This combines with the pilot pin on the journal to produce a low coefficient of friction to resist seizure and wear.

All bearing materials must be made of toughened steel which has a high resistance to chipping and breaking under the severe loading they must support. As with all rock bits roller cone drill bits components, heat treatment used to strengthen the steel.

The most important factors of the design of the bearings assembly is the space availability. Ideally the bearing should be large enough to support the applied loading, but this must be balanced against the strength of the journal and cone shell which could be function of the journal diameter and cone shell thickness.

The final design is a compromise which ensures that, ideally, the drill bits bearings will not wear out before the cutting structure (all the tricone bits, rock bits, roller rock drill bits components should wear out evenly). However, the cyclic loading imposed on the bearings will, in all cases, eventually initiate a failure. When this occurs the balance and alignment of the assembly is destroyed and the cones lock onto the journals.

Post time: Jan-13-2023