YINHAI Product Line

The high-quality YINHAI product line bits are designed for drilling various types of wells

Sizes

From 5 7/8” to 6 3/4”

5 7/8”- 6 3/4”

Seals & Bearings:

5 7/8”to 6 3/4”

Bits of this line have a reliable sealed journal bearings system which provides a stable bit performance while drilling with up to 120~50rpm.

Cutting Structures

Hardfaced steel teeth or application-specific tungsten carbide inserts are used in cutting structures.

Tungsten carbide inserts

Inner and Nose Rows -Scoop Inserts

Gauge Rows -Chisel Inserts

Gauge Bevel Protection -Flat Insert

Leg and Shirttail protection

Bit stabilization system is available in two options: with stabilization pads on side nozzles or without them.

Legs are protected by hardfacing and tungsten carbide inserts.

For highly abrasive formations diamond coated tungsten carbide inserts can be used.

Hydraulics

Effective bottom-hole cleaning and anti-balling are provided by an optimized hydraulics system.

The system consists of three side nozzles Pressure compensation syste

Lubrication system

Precisely designed and processed lubrication system and the use of new type of synthetic grease can improve balancing speed of the pressures inside and outside of the bearing package and achieve better protection of the bearing and seal system of the bit.

MAIN STRUCTURE FEATURES

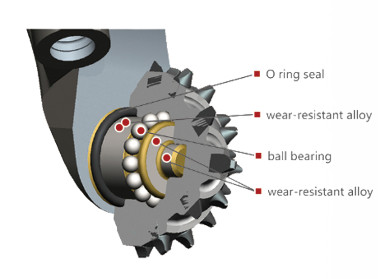

Journal bearing .Hardfaced head bearing surface.Cone bearing surface is plated by using high composite solid lubricating material. Load capacity of bearing is greatly improved.

● More wear resistant and high temperature resistance increase the reliability of the seal.

● With carbide compacts of high strength and high toughness and advanced carbide compact layout, TCI bits perform better on wear resistance and excellent cutting ability .

● Advanced gauge protection improve the working life of bits

Bearing Design

Head Bearing of YH bit is adopted welding technology with wear-resistant alloy on surface head-faced.Composite solid lubricating material and new type of grease are applied to improve bearing’s working environment. The bearing can receive higher WOB under using those bearing technology.

Lubrication System

Precisely designed and processed lubrication system and the use of new type of synthetic grease can improve balancing speed of the pressures inside and outside of the bearing package and achieve better protection of the bearing and seal system of the bit.

Gauge Protection

Inserts on heal row with good wear-resistance to enhance

Gage protection.

Thicken hard-facing on shirttail to protect the seal.

Inserts on leg to improve further capability of gauge protection.

SPECIAL DESIGN DOUBLE RUBBER SEALED JOURANL BEARING 17 1/2”-20”(Following photos show the double bearing special design)

Post time: Nov-19-2021