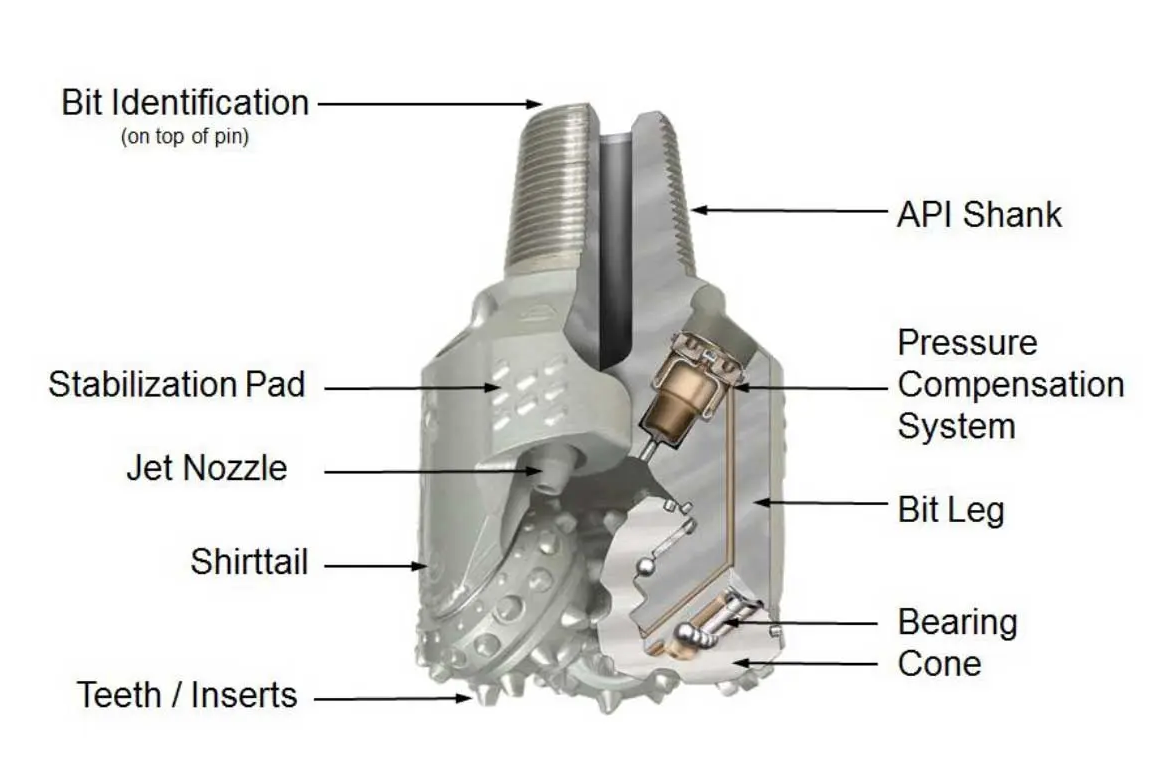

The tricone drilling bit body consists of:

1.the thread connection,or shanks, which attaches the tricone bits to the string.

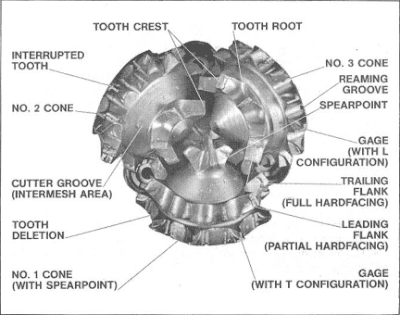

2.the bearing pin on which the cones are mounted.

3.the lubricant reservoir, which contains the lubrication system supply for the bearing, watercourse through which the drilling fluid flows to clean from the holes.

The individual body section, including the integral bearing pins, are machined from forging or casting of a nickel-chromium- molybdenum alloy steel of carburized grade. The bearing pin portion is selectively carburized (surface hardened) to provide a deep, wear-resistant case. The section is then oil-quenched hardened and tempered, resulting in wear-resistant bearing surface.

Each individual body component consists of a leg and bearing pin, Tricone Three Cones Drill Bits have three segments. The individual segments are welded together to form the complete bit body.

Roller bits Tricone Drill Bit Shanks.

The shank of the Rock Roller Tricone Bits connect the body to the bit sub or drill collar. The thread connection is API regular thread, semi-rounded thread. Connection sizes are fit for various diameter drill bits.

The top of the shank is used for identification. It contains such information as:

1.bit diameter inch

2.assembly number

3.type

4.manufacturer’s trademark

5.serial number

6.IADC code

The shank and shoulder provide the fluid sealing between the tricone bit and the drill string. The threads will not form a pressure-tight seal and will result in pipe washout problem if the cone Drill Bit is not made up properly. It is important, therefore, to ensure that the shank seat and shoulder are clean.

Post time: Sep-27-2022