YINHAI ROCK BITS FACTORY PROFILE

1. YINHAI Location:

-Our company is located in Junziguan Industrial District, Hejian city, Hebei province, where is the main source of rock bits manufacturing and distribution of China, and is only 200km from Beijing Capital International Airport.2. YINHAI Business/Market:

— We are a 100% factory (manufacturer) of Tricone Drill Bits (both Steel Milled Tooth Bit and Tungsten Carbide Inserts Bit) from 3″ to 20″

& PDC Drill Bits from 3 1/2 to 17 1/2 inch, with 13 years’ experience of producing Rock Drilling Bits.

— We have passed factory audit by SGS. All of drill bits are strictly according to API standard.

— We are competent to design and produce the Drilling Tools for Water / Oil/Gas well drilling, Mining, Piling foundation and HDD drilling, like Single Roller Cones Bits/Cutters/Palms/ Segments/Sections, Drag Bits, Hole Openers/Rock Reamers, Core Barrel and other customized bits depending on the utility demand.

— YINHAI bits have been being sold well and running stably in Asia, Europe, Africa and Amercia, such as: U.S.A, France, Saudi Arabia, Algeria, Singapore, Italy, India, Chile, Poland, Tunisia, Russia etc.

—We adhere to the principle of “ Win the customer by attractive quality and price” and “Create value for customers by professional technology and experienced service”.

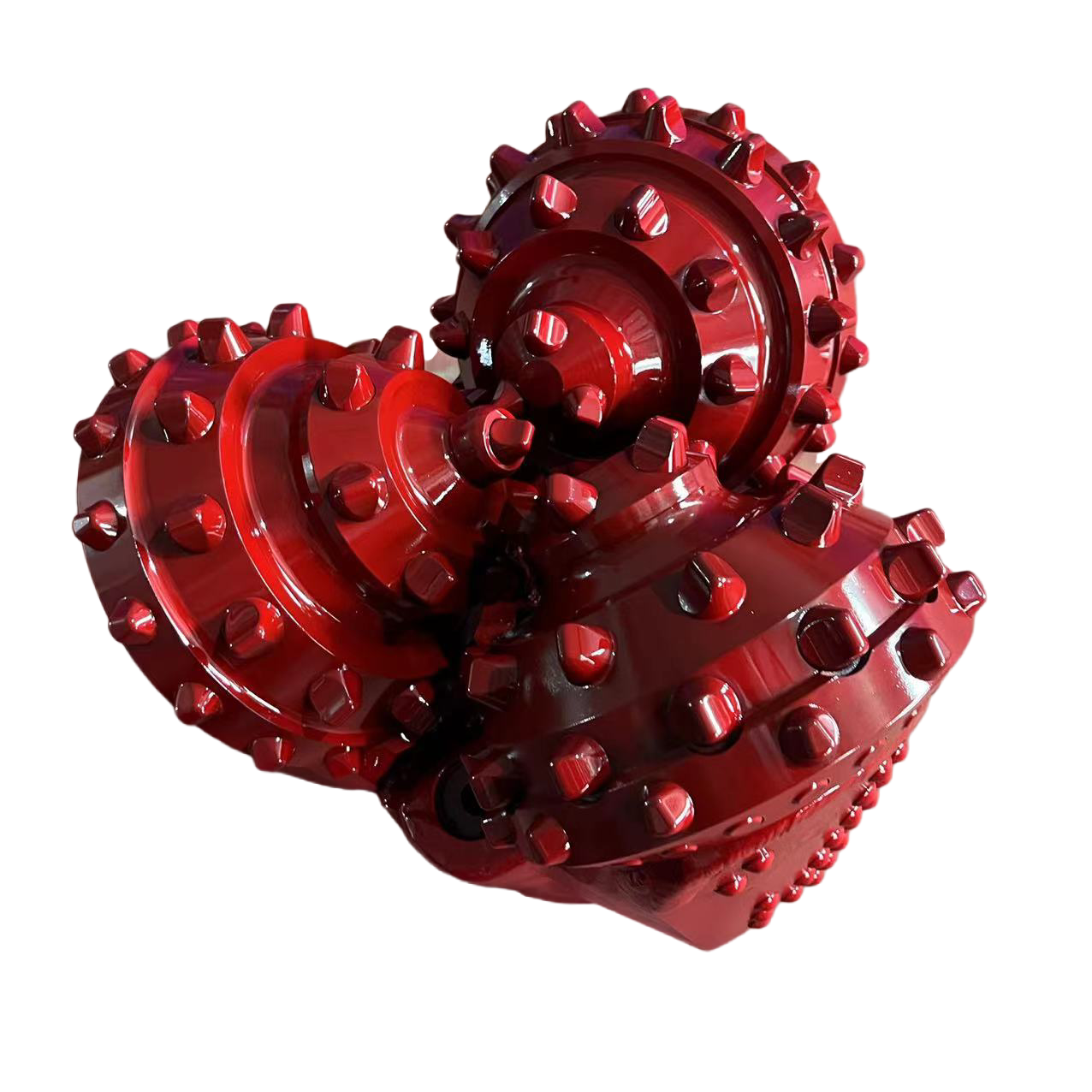

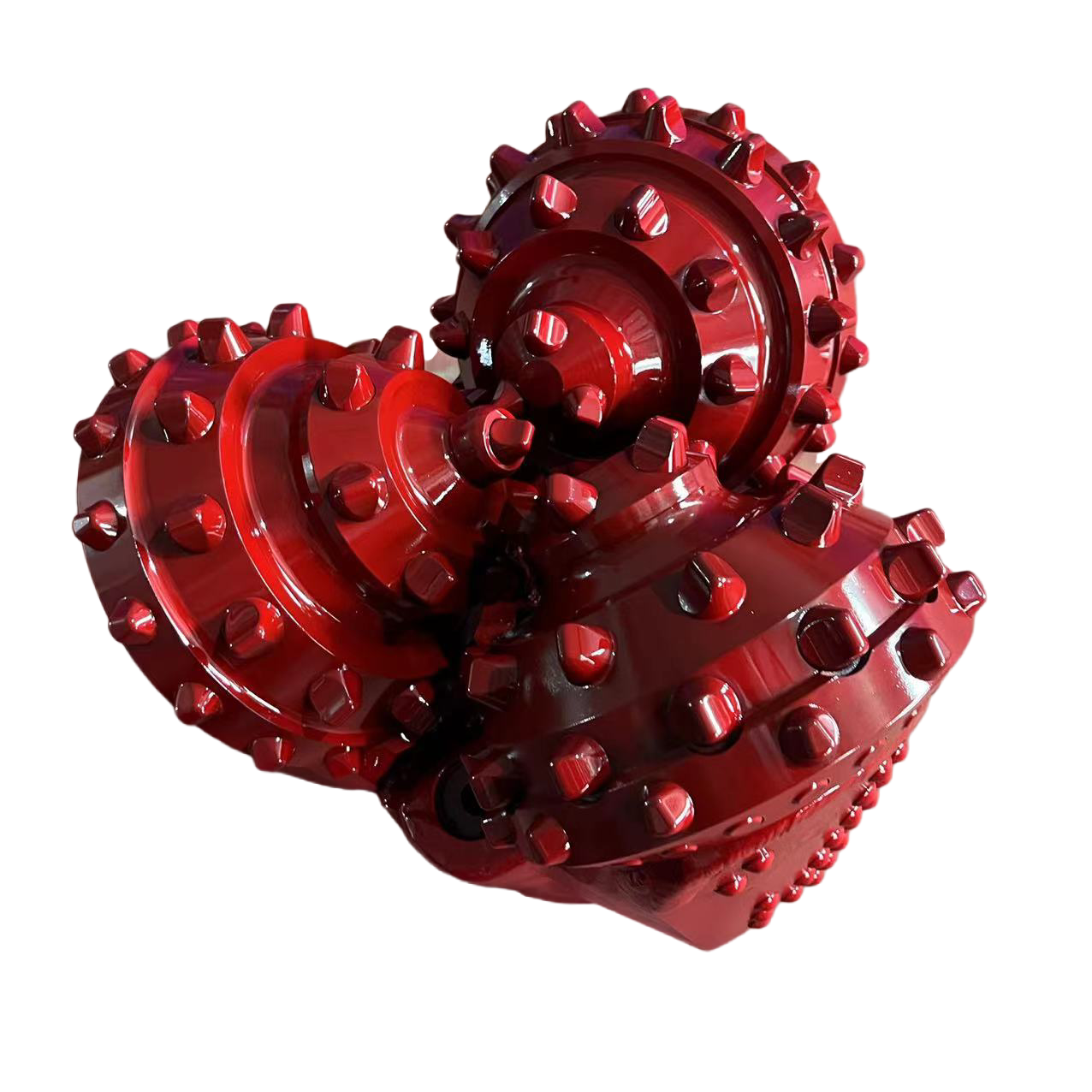

YINHAI TCI & MT TRICONE BITS OVERVIEW

YINHAI WORKSHOP DESIGN & PRODUCTION & WAREHOUSE

YINHAI Tricone Bits/Roller Cone Bits Details:

Tungsten Carbide Inserts Bits /TCI & Steel tooth tricone bits/MT, from 3 7/8 to 28 inch (3 7/8″ ~ 28″).

— Our advantage & features:

1. Bearing polishing process improves the service life

2. Hardfacing and Tungsten Carbide Inserts for Leg and shirttail protection

3. Heel Inserts and Build up welding on the Steel milled teeth

— Since the end of 2021, our factory has added a new process for better bearing performance–bearing polishing,

We polish the bearing after finished turning, After polishing, it is very smooth like mirror, very very smooth and shining.

Extend the service life of our drill bits, allowing customers to get a better quality product for the same value.

— YINHAI TRICONE BITS, ENGINEERED TO DRILL:

IADC 117/217/327, IADC 417/437/517/537/637, Steel Milled Tooth and Chisel/ Scoop/ Conical/ Sphrical teeth

Suitable for Water, Oil, Gas, Geothermal well drilling, Mining and HDD drilling

| NO. |

IADC |

Recommend Parameters |

Suitable Formation |

WOB

(KN/mm) |

RPM

(r/min) |

| 1 |

116,117 |

0.35~0.8 |

150~80 |

Extremly soft formation with low compressive strength and high drillability,such clay,mudstone,cretaceous |

| 2 |

126,127 |

0.35~0.9 |

150~70 |

Soft formation with low compressive strength and high drillability,such as mudstone,gypsum,salinastone,soft shale,soft limestone |

| 3 |

136,137 |

0.35~1.0 |

120~60 |

Soft to mid-soft formation with low compressive strength and high drillability,such mid-soft shale,anhydrite,mid-soft limestone,mid-soft sandstone and soft formation with hard interbeds |

| 4 |

216,217 |

0.4~1.0 |

100~60 |

Soft to medium formation with low compressive strength,such as mid-soft shale,mid -soft limestone,mid-soft sandstone and soft formation with hard interbeds |

| 5 |

246,247 |

0.4~1.0 |

80~50 |

Mid-hard formation with high compressive strength,such as hard shale,limestone,sandstone and dolomite |

| 6 |

417,437,447 |

0.35~0.9 |

150~70 |

Extremely soft formation with low compressive strength and high drillability,such as clay,mudstone,cretaceous,gypsum,salinastone,soft shale and soft limestone |

| 7 |

517,527 |

0.35~1.0 |

140~60 |

soft formation with low compressive strength ,such as mudstone,gypsum,salinastone,soft shale and soft limestone |

| 8 |

537,547 |

0.45~1.0 |

120~50 |

Soft to medium formation with low compressive strength,such as mid-soft shale,mid -soft limestone,mid-soft sandstone and medium formation with harder abrasiveness interbeds |

| 9 |

617,627 |

0.45~1.1 |

90~50 |

Mid-hard formation with high compressive strength,such as hard shale,limestone,sandstone,and dolomite |

| 10 |

637 |

0.5~1.2 |

80~40 |

Hard formation with high compressive strength,such as sandstone,limestone,dolomite and anhydrite,marble |

Note :The upper limits of WOB and RPM in above table should not be used simultaneously.

FAQ:

1.Q: Is your company a distributor or a manufacturer?

A: Manufacturer, We are a 100% real factory of Rock Drill Bits, with 13 years’ experience in manufacturing.

We have experienced design, production and sales teams, also provide you with OEM service.

Welcome to book a video-call to inspect our factory.

2.Q: How about your products?

A: Both standardized tricone bits and PDC bits produced strictly according to API and rock bits-customizing used in various construction works are provided.

Copy link to view our factory Verified SGS report, SGS Serial NO.: QIP-ASI206122

https://yinhaibits.en.made-in-china.com/company-HEJIAN-YINHAI-ROCK-BITS-MANUFACTURE-CO-LTD-.html

3.Q: What kind of packing do you have?

A: Ply Wooden boxes (free of fumigation); Cartons; Steel Boxes; Customized Packages.